More than two-thirds of the world’s energy is wasted as heat. Paul W Kincaid’s latest renewable energy technology design was designed to utilize thermal conduction to convert heat into renewable energy. The undeveloped technology (undeveloped due to lack of funding) utilizes the heat from asphalt roofs to produce renewable energy with zero CO2 emissions.

Thermal conduction is the transfer of heat energy from one substance (asphalt shingles) to another (metal sheets or foils) or within a substance. Conduction is a very effective method of heat transfer in metals.

Asphalt roofs are the logical choice for harnessing CO2 free renewable energy. Dark asphalt shingles absorb an enormous amount of solar radiation. Nearly 90% of solar energy that hits our rooftops is absorbed and is then converted to heat. During the day, your roof can reach very high temperatures. For example, a standard asphalt shingle can be as hot as 60 – 75 °C.

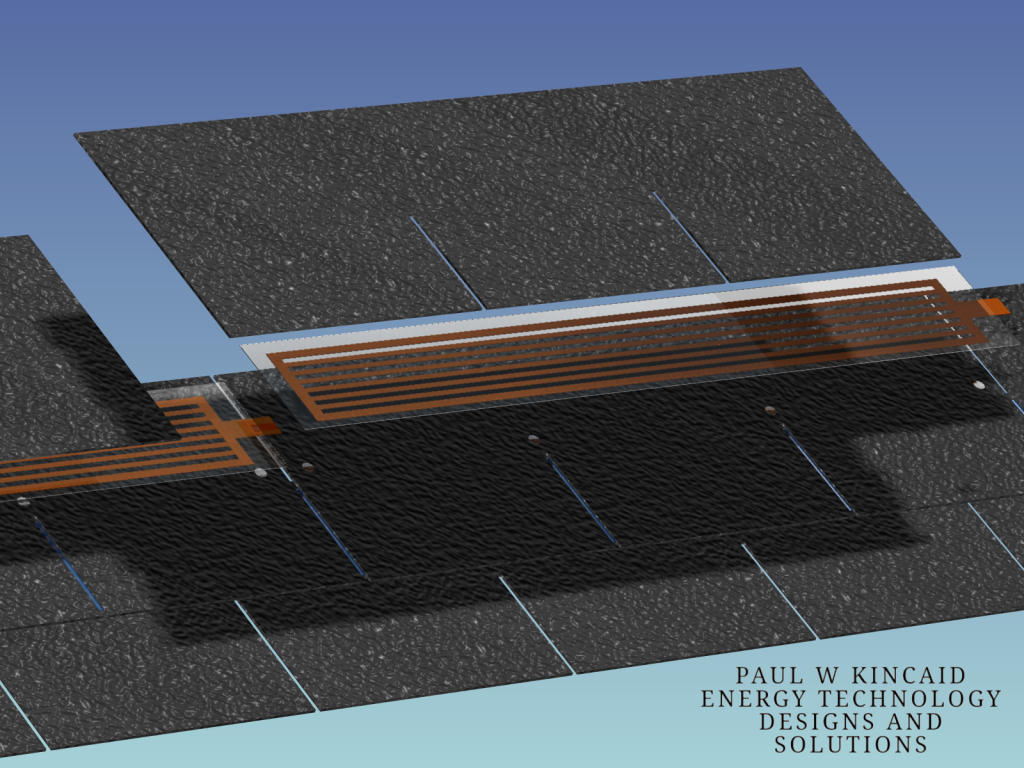

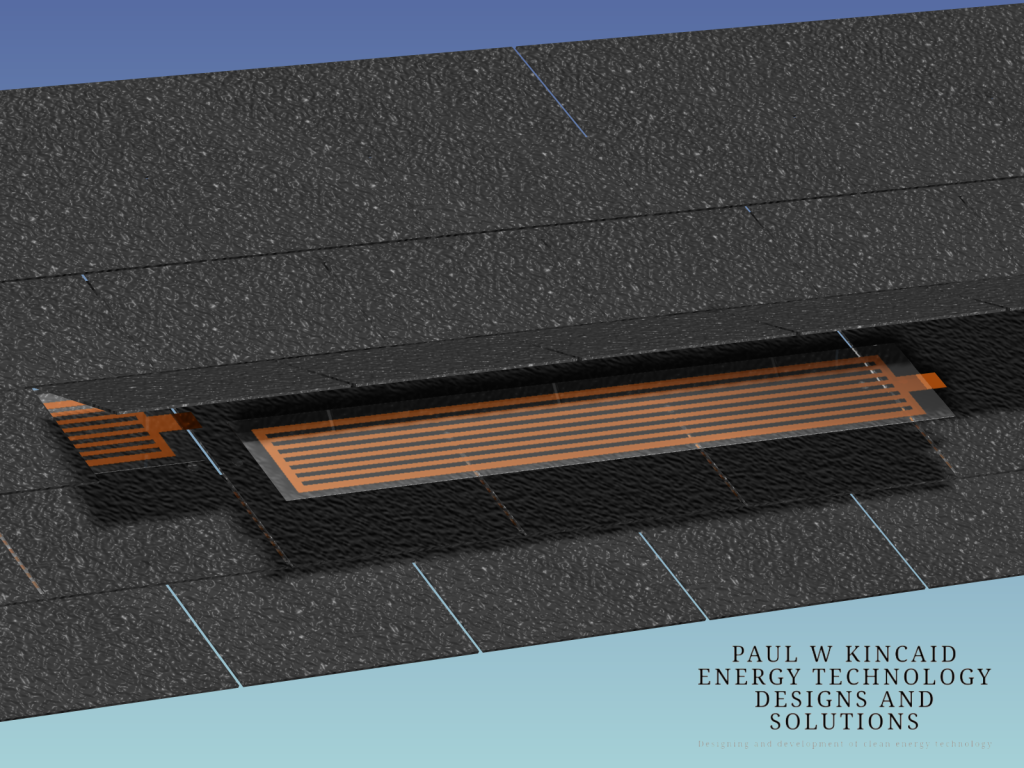

This renewable energy technology was designed to be installed quickly and easily. The insulated “thermal conduction panels” were designed to be installed on either an existing roof or a new roof.

Need more energy? Install and connect more thermal conduction panels “in series” under your roof’s asphalt shingles.

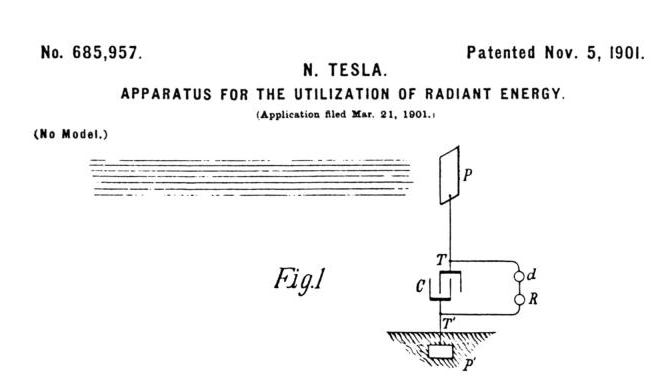

This renewable energy technology design is based on a method Nikola Tesla used over 120 years ago to harness radiant energy. In the 1901 granted patent US685958A – Method of utilizing radiant energy Nikola Tesla harnessed radiant energy using a single sheet of highly polished and insulated metal plate.

“The insulated plate or conducting-body should present as large a surface as practicable to the rays or streams of matter, I having ascertained that the amount of energy conveyed to it per unit of time is under otherwise identical conditions proportionate to the area exposed, or nearly so.” …

“My present application is based upon a discovery which I have made that when rays or radiations of the above kind are permitted to fall upon an insulated conducting body connected to one of the terminals of a condenser, while the other terminal of the same is made by independent means to receive or to carry away electricity, a current flows into the condenser so long as the insulated body is exposed to the rays, and under the conditions hereinafter specied an indefinite accumulation of electrical energy in the condenser takes place. This energy after a suitable time interval, during which the rays are allowed to act, may manifest itself in a powerful discharge, which may be utilized for the operation or control of mechanical or elecitrical devices or rendered useful in many other ways.” Nikola Tesla patent US685957A

Reading Nikola Tesla’s Patent US685957A we can clearly see from the information and images filed with the patent that Nikola Tesla used an insulated metal plate to harness energy – energy that is transferred by electromagnetic radiation, such as light, X-rays, gamma rays, and thermal radiation.

What “metal” did Nikola Tesla use in the patent for the insulated metal plate? Copper?

Copper has the highest conductivity of any non-precious metal and one that’s 65% higher than aluminum. Copper has the best electrical conductivity of any metal, except silver. Copper is a good conductor of heat (about 30 times better than stainless steel and 1.5 times better than aluminum). Most metals are pretty good conductors; however, apart from silver, copper is the best. Each copper atom has lost one electron and become a positive ion. So copper is a lattice of positive copper ions with free electrons moving between them. Electrons can move freely through the metal. For this reason, they are known as free electrons. They are also known as conduction electrons, because they help copper to be a good conductor of heat and electricity.

How much energy can be potentially produced by developing renewable energy technology that harnesses energy via thermal conduction?

“At high noon on a cloudless day, the surface of the Earth receives 1,000 watts of solar power per square meter (1 kW/m 2 ).” Caltech US Department of Energy, Office of Basic Energy Science , Washington, DC report under CONVERSION OF SUNLIGHT INTO ELECTRICITY p.15

“the Earth system—land surfaces, oceans, and atmosphere—absorbs an average of about 240 watts of solar power per square meter (one watt is one joule of energy every second)” NASA

Won’t know for sure until the thermal conduction panels are developed and installed on a roof and metered.

In the meantime, one asphalt shingle measures 12″ x 36″. Six thermal conduction panels installed under 6 shingles would therefore give you approximately 1 square meter of thermal conduction surface area. Six thermal panels are needed to make approximately 1 square meter because 1 thermal conduction panel is placed under half of a shingle.

That means 6 panels have the potential to harness from 240 to 1,000 watts of solar power.

Methodology

The flow of electrons is what creates electrical current. Electrical energy is energy produced by the movement of certain particles. This flow of particles is called electric current. Currents go in one direction at a time.

In order to energize a light bulb or turn on a computer, we need to produce a continuous electric current. To do this, we need an energy source. Common energy sources include the Sun, batteries and generators. An electric current also needs a path along which it can travel. An electric circuit is a pathway through which electric current flows.

Wires and the thermal conduction panel’s elements provide a path through which current can flow. Wires and elements are made from materials that carry, or conduct, electrons more easily than other materials. Materials that conduct electrons easily are called conductors. Copper and aluminum are good conductors. Wires are wrapped with a material called an insulator. This material does not easily carry electrons. Insulators keep the conductors inside a wire from touching each other and interrupting the flow of electrons. Rubber, plastic, and glass are good insulators. The spacing of the thermal conduction panel’s elements keep the conducting elements from touching each other and interrupting the flow of current.