Published on: September 12, 2023

Electric cars don’t need very expensive battery packs and they don’t need to be plugged in to be recharged. Nikola Tesla successfully demonstrated in the 1930s that an electric car can be powered and driven using 3 mass produced automobile parts.

- A single 12 volt battery

- an alternator and

- an ignition coil

Nikola Tesla removed the gas engine from a Pierce Arrow and replaced it with a 80 horsepower AC electric motor. Tesla then built a power receiver using 12 vacuum tubes, some wires and resistors. Tesla installed the compact power receiver in the dash of the Pierce Arrow and then connected the receiver to an antenna mounted on the rear of the car and to a 80 horsepower AC electric motor. This was reported by the Dallas Morning News.

Dallas Morning News

The Electric Auto that almost triumphed: Power Source of ‘31 car still a mystery

by A.C. Greene,

January 24th, 1931

It is a mystery car once demonstrated by Nikola Tesla, developer of alternating current, that might have made electrics triumphant.

Supported by the Pierce-Arrow Co. and Westinghouse in 1931, he took the gasoline engine from a new Pierce-Arrow and replaced it with an 80 horsepower alternating current electric motor with no external power source. From the electric motor trailed two very thick cables, which connected with the dashboard. In addition, there was an ordinary 12-volt storage battery. (”There was a 12-volt Willard battery installed in the car, but it was for the lights only and much too small to run the car. In any case.”) The motor was rated at 80 horsepower. Maximum rotor speed was stated to be 30 turns per second (1800 rpm). A 6-foot vertical antenna rod was fitted into the rear section of the car.

At the appointed time, Nikola Tesla arrived from New York City and inspected the Pierce-Arrow automobile. He then went to a local radio store and purchased a handful of tubes (12 radio vacuum tubes), wires and assorted resistors. A box measuring 24 inches long, 12 inches wide and 6 inches high was assembled housing the circuit. The “power receiver” was then placed into the dashboard of the car and its wires connected to the antenna and to the air-cooled, brushless motor. Two rods 1/4” in diameter stuck out of the box about 3” in length. Tesla began making adjustments on the “power receiver”

Mr. Tesla got into the driver’s seat, pushed the two rods in and stated, “We now have power”. He put the car into gear and it moved forward! This vehicle, powered by an A.C. motor, was driven to speeds of 90 m.p.h. and performed better than any internal combustion engine of its day! One week was spent testing the vehicle. Several newspapers in Buffalo reported this test. When asked where the power came from, Tesla replied, “From the ethers all around us”. Several people suggested that Tesla was mad and somehow in league with sinister forces of the universe. He became incensed, removed his mysterious box from the vehicle and returned to his laboratory in New York City. His secret died with him!

A nephew of Nikola Tesla later reported:

under the hood, there was a brushless electric motor, connected to the engine. The engine was said to measure 40” long by 28” diameter.

Take note that he reported that there were 2 electric motors in the engine compartment. “A brushless electric motor” was “connected to the engine” – a 80 horsepower brushless electric motor. That’s significant because it starts to unravel the mystery as to how Nikola Tesla powered the Pierce Arrow with only one 12 volt battery installed in the car.

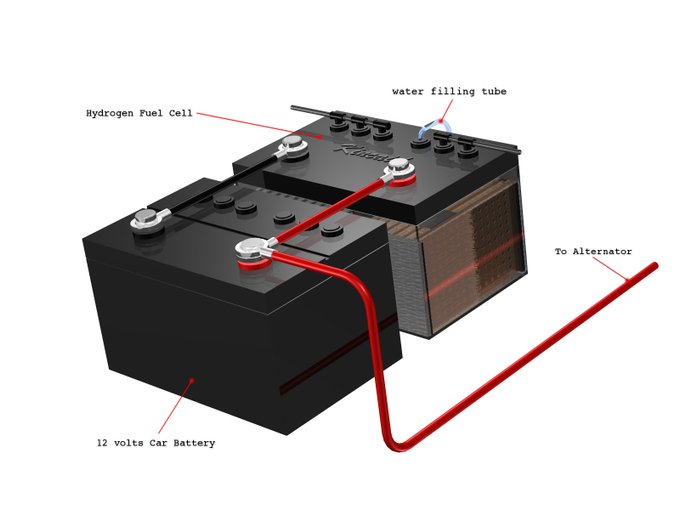

We know that there was only one 12 volt battery in the car because the Dallas Morning News reported that there was just one 12 volt battery. The tune-up manual for the Pierce Arrow states that the Pierce Arrow’s battery was a Willard Type WJ 4-15. Capacity – 128 Amp hour (20 hr. rate).

There is no mention in the Dallas Morning News article or by any witnesses that Nikola Tesla removed the alternator of the Pierce Arrow. It just stated that the gas combustion engine was removed and replaced with an 80 horsepower AC electric motor.

Alternators are used in all gas combustion engine automobiles to charge the battery and to power the electrical system when the engine is running. Even the Ford Model T automobiles from 1919 to 1927 had a 12 volt negative ground Delco style alternator.

An alternator was the brushless electric motor that Tesla’s nephew reported was connected to the engine. Nikola Tesla made use of the alternator to continuously recharge the Pierce Arrow’s “single” 12 volt Willard battery.

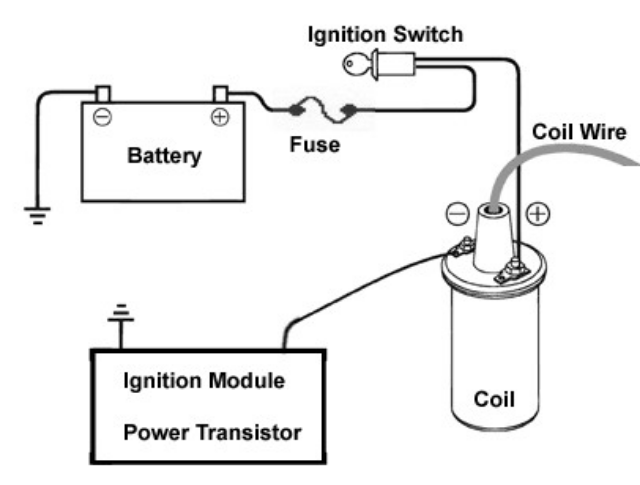

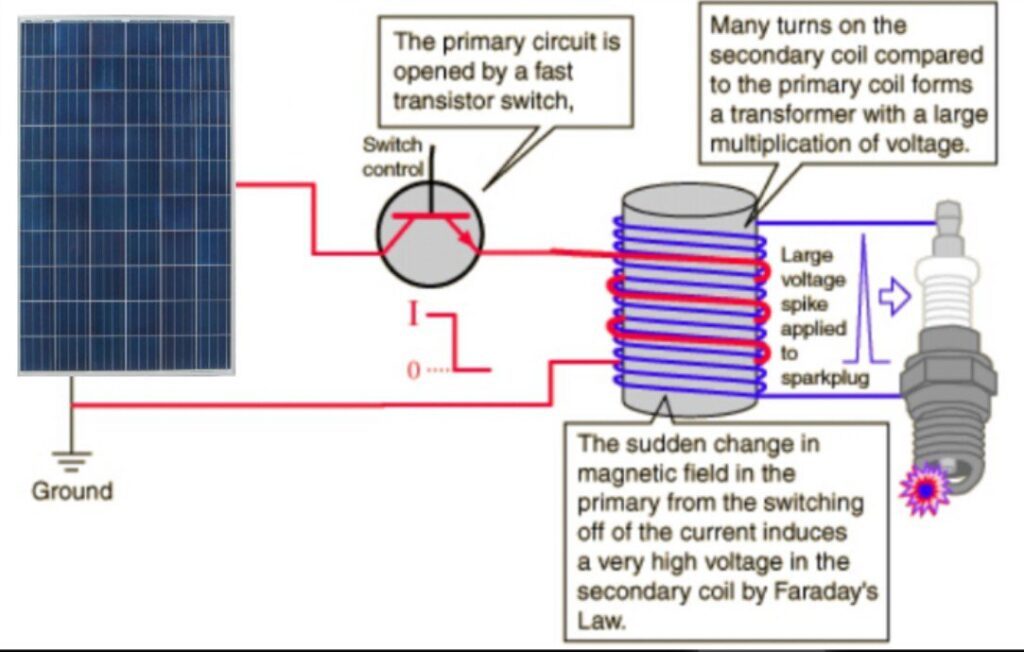

There’s no mentioning that Tesla removed the Pierce Arrow’s ignition coil either. An ignition coil converts 12 volts to 30-40 kVs using a transistor or in Tesla’s case, vacuum tubes.

Ignition coils existed back in the 1930s too. We know there was an ignition coil installed in the Pierce Arrow before it was converted into an electric motor car. The tune-up manual stated that the 1931 Pierce Arrow ignition coil was a Delco-Remy 526-B ignition coil. The Pierce Arrow tune-up manual also stated that it was mounted on the dash. A 12 volt battery wire also enters the dash and is connected to the ignition switch.

The Pierce Arrow tune-up manual stating and confirming that the Pierce Arrow was equipped with an ignition coil and that it was mounted on the dash is a significant finding because Nikola Tesla’s

“power receiver” was then placed into the dashboard of the car and its wires connected to the antenna and to the air-cooled, brushless motor.

An ignition coil (also called a spark coil) is an induction coil in an automobile’s ignition system which transforms the battery’s low voltage to the thousands of volts needed to create an electric spark in the spark plugs to ignite the fuel. It is entirely plausible that Nikola Tesla used the Pierce Arrow’s ignition coil to transform the 12 volt car battery’s low voltage into thousands of volts (kVs) needed to power the electric motor.

An AC electric motors requires more than 12 volts of AC current. So all Nikola Tesla needed to do is use the Pierce Arrow’s ignition coil to transform the Willard battery’s 12 volts into the required voltage needed to power the 80 horsepower AC electric motor.

A reasonable person would therefore conclude that the 50 amps 12 volt alternator was used to continuously recharge the Willard 12 volt battery (128 Amp. hour) so that the Delco-Remy ignition coil could simultaneously keep on producing the required voltage needed to power the 80 horsepower AC electric engine. As a result, an electric car owner would never have to stop to charge or recharge an electric vehicle. The electric car would charge or recharge itself while it was driven.

The Dallas Morning News reported that there was a battery in the vehicle but it wasn’t used as the source of power. That’s isn’t entirely true. The battery was involved in powering the vehicle. Vacuum tubes were used to make a small AC signal voltage into a larger AC voltage, thus amplifying it. A vacuum tube is a “valve” for electricity. Vacuum tube amplification uses a small amount of electric charge to control a much bigger amount of electricity that travels through the vacuum in a tube. Vacuum tubes require a filament voltage of at least 6.3 volts to produce high AC voltages. In the early days of electronics, vacuum tube (called valves in British contexts) devices were powered by batteries.

Batteries provided the voltages required by vacuum tubes in early radio sets. Three different voltages were generally required, using three different batteries designated as the A, B, and C battery. The “A” battery or LT (low-tension) battery provided the filament voltage.

Therefore, 3 automobile parts,

1) a single 12 volt battery,

2) an alternator and

3) an ignition coil

could be repurposed to produce enough energy to power any electric car today. Nikola Tesla proved it could be done 92 years ago.

Another mass produced electrical component can be used instead of a 12 volt car battery or be added to ensure that the electric car motor is continuously provided with the sufficient power to operate optimally. A super capacitor.

“One of the best features of supercapacitors is fast charging and discharging time that makes them suitable for many applications requiring rapid charge/discharge cycles and high-power bursts such as automobiles, buses, trains, cranes, and elevators.” ScienceDirect

Supercapacitors also have a much longer lifespan than batteries. A regular battery can handle around 2000-3000 charge and discharge cycles, while supercapacitors can usually sustain more than 1,000,000.

The power source of Nikola Tesla’s 1931 Pierce Arrow car has been solved – a single 12 volt battery.

Donate an electric car without the battery packs installed and it will be proven, once again, that a single 12 volt battery can power an electric car.