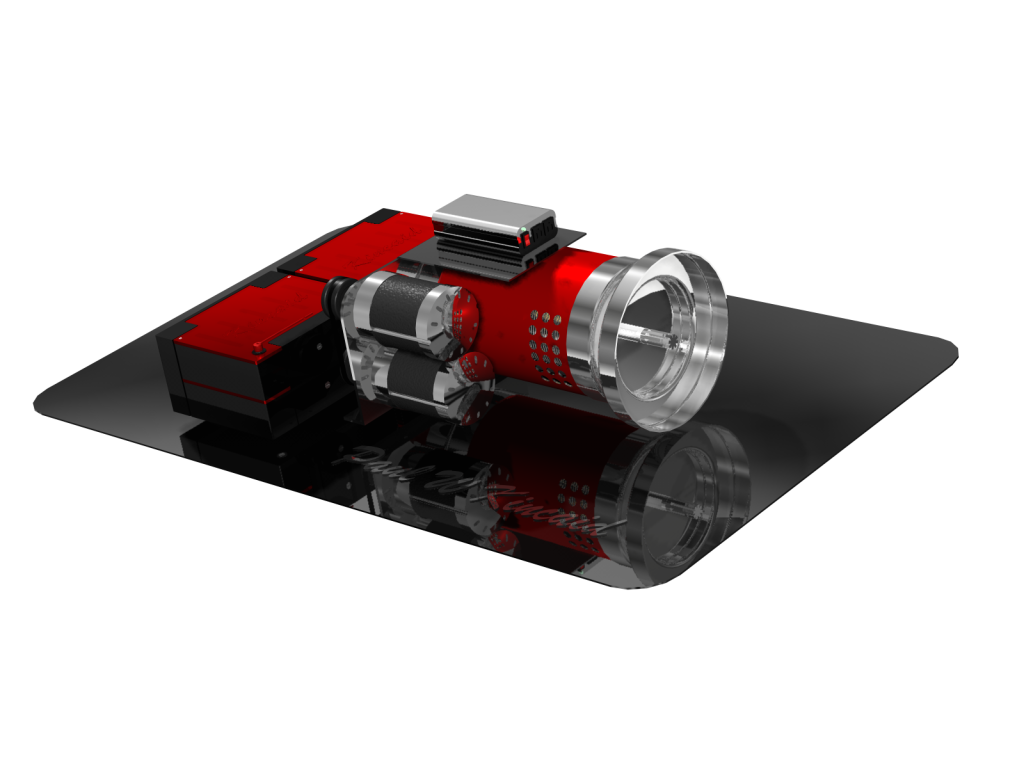

Drive-charge EV power system designed by NCIO Director Paul W Kincaid (Moncton NB Canada). Designed to power an electric vehicle great distances without having to stop to recharge. Designed so that you’ll never have to pay to drive or recharge an EV. Concept proven 90 years ago by Nikola Tesla.

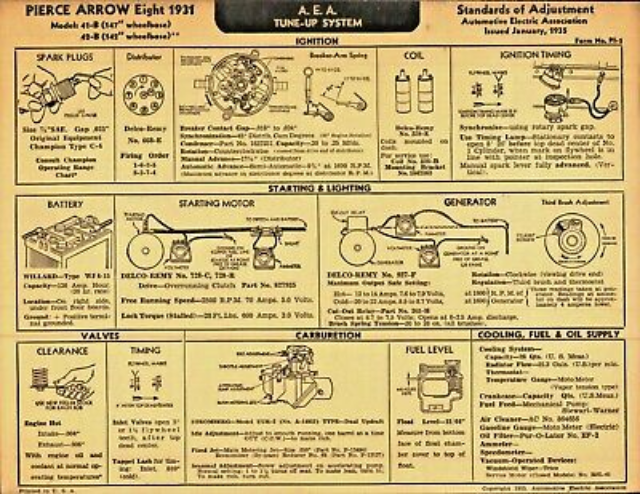

In 1931 Nikola Tesla powered a 1931 Pierce Arrow with a 80 horsepower AC motor with just 1 car battery, an alternator and an ignition coil. The newspaper left out these vital details when they reported what Nikola Tesla had achieved.

The media mislead everyone by claiming that a single car battery was only in the vehicle to power the lights. The battery was needed to power the vacuum tubes in Nikola Tesla’s power receiver. The vacuum tubes can’t function without a battery.

The media also left out the fact that the 80 horsepower AC motor was attached by a serpentine belt to a 50 amp alternator and that the dash had an ignition coil installed which Tesla hooked up a small power receiver to.

The 3 gas combustion engine parts powered the 80 horsepower AC motor at speeds up to 90 mph for hundreds of miles.

The 50 amp alternator played the most important role in powering the Pierce Arrow with a 80 horsepower AC electric motor for great distances.

A typical mass produced alternator is designed so that the field (in the rotor) can be driven with just one 12 volt car battery and produce at least 14 volts DC on the stator (via diodes) to continously charge the car battery at idle speed. The vehicle’s pulleys and belts usually provide a RPM boost at idle. At maximum engine speed (6000-9000 RPM), the alternator will spin at up to ten times faster than when idling, and the voltage on the stator (with 12V on the field) will then be as much as 10x higher, or as high as 140 volts AC (three phase) and nearly 200 volts DC through the diodes.

A typical 50 amp alternator like the one that was in Nikola Tesla’s electric car could therefore “continously” produce 200 x 50 = 10 kW or 15 HP.

The pulleys and belts will in practice limit the power output of the alternator. So to produce more kW or HP from an alternator one could:

1) bypass the regulator so it applies full voltages to the field coil, from another alternator or battery, at light loading, the alternator could put out 120 volts DC. at light loading or

2) gear up the alternator, since an alternator must turn about 5000 RPM to produce 120 volts.

Putting a larger pulley on the electric motor will achieve a gear up whose ratio is proportional to the ratio of the pulley diameters. For instance, an electric motor running at 2600 RPM must be Geared to turn the alternator at 5200 RPM, We need to gear the alternator up by 5200 / 2600 = factor of 2. Therefore, the pulley on the electric motor should be twice the diameter as the pulley on the alternator.

There’s an even simpler way to get more kW or HP from an alternator. Install an alternator with higher amps or add one or more alternators to the EV power system.

A Leece Neville 230 Amp Alternator for a 6.0L & 7.3L Ford can do 230 amps continuous output. A 230 amp high amp full duty alternator will typically have a 100% duty cycle. This alternator can generate continuously at 230 amps into a restive load.

This commercial grade alternator is a replacement for the stock 6.0L and 7.3L ford alternators. The units are USA Made and have a proven history of performance and reliability. Tens of thousands of big rigs run Leece Neville/Prestolite alternators.

100+ year old auto part instantly and continously converts 12 volts to 30-60,000 volts (30-60 kVs)

The 1931 Pierce Arrow tune-up manual confirms that Nikola Tesla’s Pierce Arrow electric car was equipped with an Delco-Remy ignition coil and that it was mounted on the dash.

An ignition coil (also called a spark coil) is an induction coil in an automobile’s ignition system which transforms the car battery’s low voltage to the thousands of volts needed to create an electric spark in the spark plugs to ignite the fuel. It is entirely plausible that Nikola Tesla used the Pierce Arrow’s ignition coil to transform the 12 volt car battery’s low voltage into thousands of volts (kVs) needed to power the electric motor.

An AC electric motors requires more than 12 volts of AC current. So all Nikola Tesla needed to do is use the Pierce Arrow’s ignition coil to transform the Willard battery’s low voltage into the required voltage needed to power the 80 horsepower AC electric motor.

A reasonable person would therefore conclude that the 50 amp alternator was used to continuously recharge the Willard battery (128 Amp. hour) so that the Delco-Remy ignition coil could simultaneously keep on producing the required voltage needed to power the 80 horsepower AC electric engine.